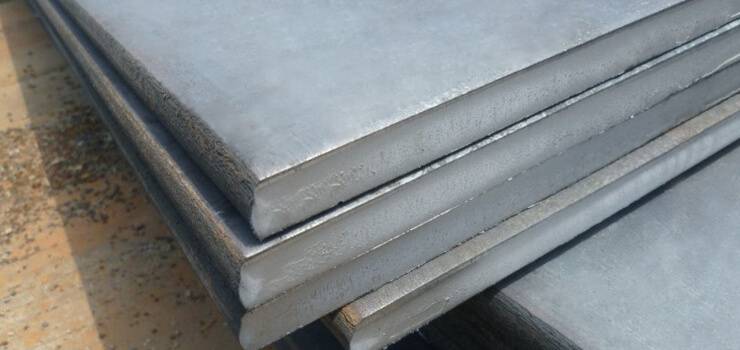

ASTM A36 plates are known for their durability, versatility, and affordability. They are widely used in construction, automotive, and manufacturing industries due to their strength and ease of fabrication. With different types available, each suited to unique applications, it’s essential to understand the properties and uses of each to make an informed choice. Below, we explore the four main types of ASTM A36 plates you should know about.

Hot-Rolled ASTM A36 Plate

The hot-rolled ASTM A36 plate is produced by rolling steel at high temperatures, usually above 1,700°F. This process ensures the steel is pliable and easier to work with, allowing it to be shaped and formed more effectively. The result is a rougher surface finish that is ideal for applications where aesthetics are not the primary concern.

Properties and Uses

Hot-rolled A36 plates are known for their strength and durability. While they might lack a refined finish, their affordability and availability in thicker dimensions make them popular for heavy-duty construction projects.

- Construction: Used in building frameworks, bridges, and large-scale structures.

- Automotive: Applied in manufacturing vehicle parts where finish quality is less critical.

- Manufacturing: Ideal for general fabrication projects that require durable, affordable steel.

The hot-rolled ASTM A36 plate is a top choice for cost-effective, large-scale structural work.

Cold-Rolled ASTM A36 Plate

Cold-rolled ASTM A36 plates are produced by rolling steel at room temperature. This process gives the plate a smoother finish and greater dimensional accuracy than hot-rolled plates. Cold-rolling also improves the strength and hardness of the steel due to work hardening.

Properties and Uses

Cold-rolled A36 plates, with a more refined appearance, are used in applications where aesthetics and precision are important. They are slightly more expensive than hot-rolled plates but offer a polished look and tighter tolerances.

- Furniture: Often used in furniture frames and other interior applications.

- Automotive Parts: Preferred for parts that need a more finished surface, such as certain vehicle components.

- Precision Manufacturing: Utilized in projects where a smooth finish and exact dimensions are essential.

For projects that prioritize appearance and precision, cold-rolled ASTM A36 plates offer both aesthetics and performance.

Galvanized ASTM A36 Plate

The galvanized ASTM A36 plate is coated with a layer of zinc to enhance its corrosion resistance. The galvanization process protects the steel from rust and other environmental factors, extending its lifespan significantly, especially in outdoor and high-moisture environments.

Properties and Uses

Galvanized A36 plates are the preferred choice for applications exposed to harsh conditions. The zinc coating acts as a barrier, preventing rust and corrosion, which is vital in construction and infrastructure projects.

- Outdoor Construction: Commonly used in outdoor structures, such as fences, light poles, and other exposed frameworks.

- Marine Applications: Ideal for docks, marinas, and structures exposed to water or high humidity.

- Agricultural Equipment: Used in farming machinery and structures frequently exposed to the elements.

If you need steel that can withstand the elements, galvanized ASTM A36 plates are the best choice for long-lasting, corrosion-resistant performance.

Pickled and Oiled ASTM A36 Plate

Pickled and oiled ASTM A36 plates undergo pickling, where the surface is treated with an acid solution to remove mill scale, rust, and other impurities. The plate is then coated with oil to prevent rusting, resulting in a clean, smooth surface ready for painting and further processing.

Properties and Uses

The pickled and oiled process gives the plate a clean, scale-free surface, making it easier to work with in applications that require a high-quality finish.

- Automotive Manufacturing: Used in frames, chassis, and other parts where a clean surface is essential.

- Pipe and Tubing: Applied in manufacturing pipes and tubes for plumbing and fluid transport.

- Machinery Components: Ideal for machinery that requires a clean, prepared surface for further finishing processes.

Pickled and oiled ASTM A36 plates are an excellent option for applications that require a smooth, clean finish with improved rust resistance.

Conclusion

In summary, ASTM A36 plates are versatile and offer options suitable for various industrial applications. The choice between hot-rolled, cold-rolled, galvanized, and pickled and oiled plates depends on your needs, including cost, durability, and finish requirements. Whether you’re working on construction, automotive, or marine projects, there’s an ASTM A36 plate to meet your needs.

For high-quality ASTM A36 plates, CSEc Plates provides a reliable supply of each type, ensuring you get the right plate for your project. From hot-rolled plates for heavy-duty construction to galvanized plates for outdoor durability, CSEc Plates has options for every application.