In the world of civil engineering and construction, polyester geogrid has become an essential material due to its strength and versatility. This specialized material is designed to provide structural support and stability in various applications, from road construction to soil reinforcement. In this article, we’ll explore the features, benefits, and applications of Polyester Geogrid for Road Construction, along with answers to some frequently asked questions.

What is Polyester Geogrid?

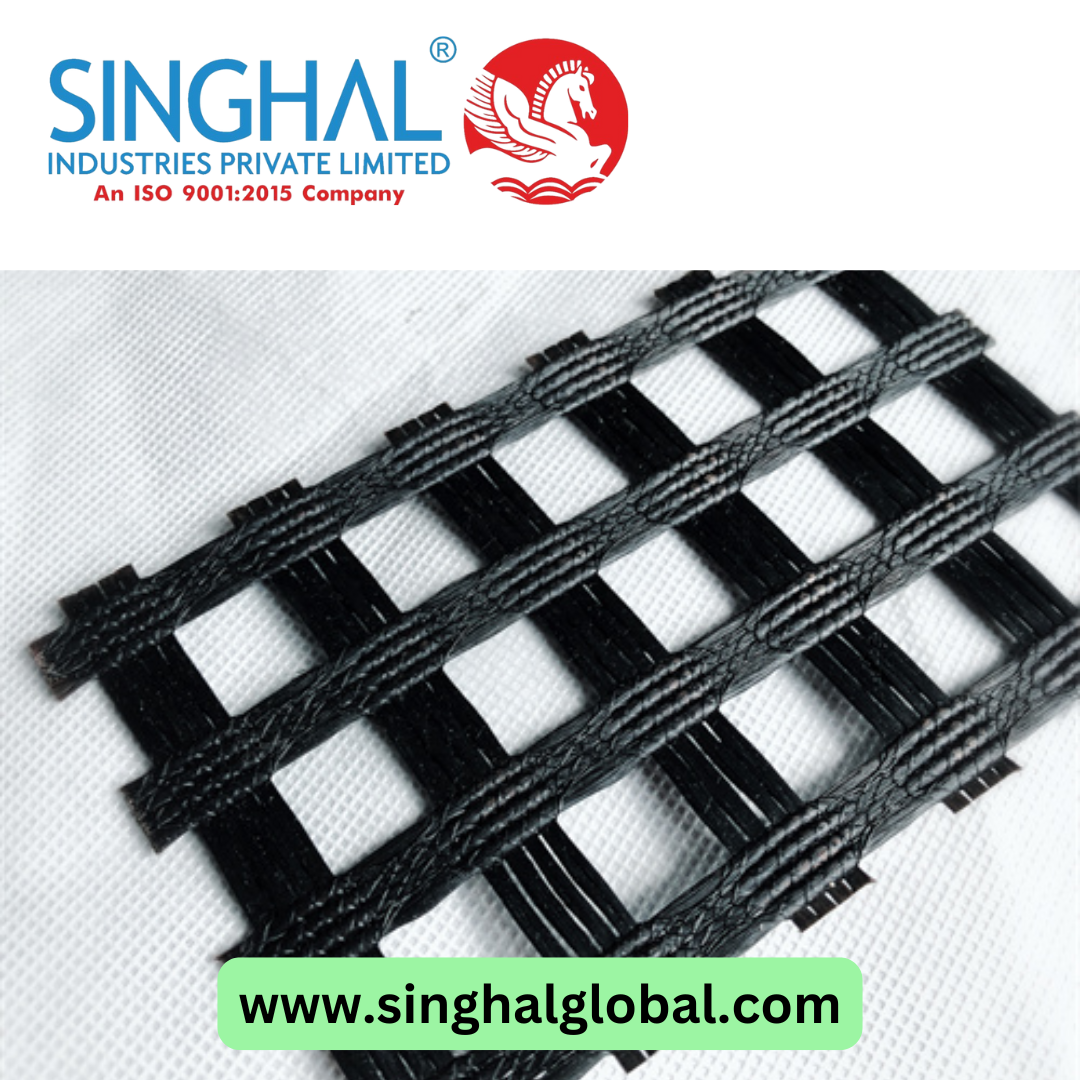

Polyester geogrid is a type of geosynthetic material made from high-strength polyester fibers. These fibers are woven into a grid-like structure, which is then coated with a polymeric material to enhance its durability and resistance to environmental factors. The resulting geogrid is highly effective at reinforcing soil and other substrates, making it a valuable tool in civil engineering projects.

Key Characteristics

- High Tensile Strength: Polyester geogrids are known for their impressive tensile strength, which helps in stabilizing soils and other materials.

- Durability: Coated with a polymeric material, polyester geogrids resist degradation from UV rays, moisture, and chemicals, ensuring long-term performance.

- Flexibility: The grid structure allows for flexibility and adaptability in various construction scenarios.

- Cost-Effectiveness: Polyester geogrids offer a cost-effective solution for soil reinforcement and stabilization compared to alternative materials.

Applications of Polyester Geogrid

The Polyester Geogrid Reinforcement are used in a wide range of applications due to their strength and versatility. Here are some common uses:

- Road Construction: Polyester geogrids are employed to reinforce roadbeds and prevent pavement damage, enhancing the longevity and stability of roadways.

- Retaining Walls: They are used in the construction of retaining walls to provide stability and prevent soil erosion.

- Embankments: Polyester geogrids help in stabilizing embankments, reducing the risk of landslides and ensuring structural integrity.

- Landfills: In landfills, polyester geogrids are used for reinforcement and to control settlement, contributing to effective waste management.

- Slope Stabilization: They are utilized in slope stabilization projects to prevent soil erosion and maintain slope stability.

Advantages of Polyester Geogrid

- Enhanced Load Distribution: Polyester geogrids distribute loads more evenly across the soil, reducing stress and improving overall stability.

- Resistance to Environmental Factors: The coating on polyester geogrids protects them from environmental factors such as UV radiation, moisture, and chemical exposure.

- Improved Soil Strength: By reinforcing the soil, polyester geogrids increase its bearing capacity and reduce the potential for settlement.

- Ease of Installation: Polyester geogrids are relatively easy to install and require minimal equipment, making them a convenient choice for many projects.

- Sustainability: The use of polyester geogrids can contribute to sustainable construction practices by reducing the need for more invasive stabilization methods.

Disadvantages

While polyester geogrids offer numerous benefits, there are a few disadvantages to consider:

- Cost: The initial cost of polyester geogrid materials can be higher than some alternative solutions, although the long-term benefits often outweigh this expense.

- Limited Degradation Resistance: Despite their durability, polyester geogrids may degrade over time if exposed to extreme conditions or improper handling.

Conclusion

The Polyester Geogrid Installation is a highly effective material for soil reinforcement and stabilization in various construction and civil engineering projects. Its strength, durability, and versatility make it a valuable tool for enhancing the performance and longevity of infrastructure. By understanding its characteristics, benefits, and applications, professionals can make informed decisions and leverage polyester geogrid to achieve successful project outcomes.

FAQs About Polyester Geogrid

Q1: What is the difference between polyester geogrid and other types of geogrids?

A1: Polyester geogrids are specifically made from polyester fibers and are known for their high tensile strength and durability. Other geogrid types, such as fiberglass or polypropylene, offer different properties in terms of strength, flexibility, and resistance to environmental factors.

Q2: How is polyester geogrid installed?

A2: Polyester geogrid installation involves laying the grid material over the prepared soil or substrate, aligning it as needed, and then covering it with additional layers of soil or construction material. It is important to ensure proper tensioning and anchoring to achieve optimal performance.

Q3: Can polyester geogrid be used in all soil conditions?

A3: Polyester geogrid is versatile and can be used in various soil conditions. However, the specific type and strength of the geogrid should be selected based on the soil characteristics and project requirements. Consulting with a geotechnical engineer can help determine the best solution.

Q4: How long does polyester geogrid last?

A4: The lifespan of polyester geogrid depends on factors such as environmental conditions, soil type, and installation quality. Generally, polyester geogrids are designed to last for many years, providing long-term stability and reinforcement.

Q5: Is polyester geogrid environmentally friendly?

A5: Polyester geogrid is considered environmentally friendly due to its durability and recyclability. By improving soil stability and reducing the need for more invasive methods, polyester geogrids contribute to sustainable construction practices.