Custom screen printing is a popular and versatile method for creating personalized shirts. Known for its durability and vibrant colors, screen printing is favored for producing large quantities of shirts with consistent quality. We provide Dallas Screen printing and if you search for custom t shirt screen printing near me then you will find us so in this article we will guide you through the process of screen printing custom shirts and explain how this method stands out compared to other printing techniques.

The Process of Screen Printing Custom Shirts

1. Designing the Artwork:

The first step in screen printing is creating the design to be printed on the shirts. This design is usually prepared using graphic design software such as Adobe Illustrator or Photoshop. The artwork is then separated into individual colors, as each color will require a separate screen during the printing process.

2. Preparing the Screens:

Once the design is finalized, it’s time to create the screens. A screen is a mesh stencil through which ink is pushed to create the design on the shirt. To prepare a screen, a mesh is coated with a light-sensitive emulsion. The design is then printed onto a transparent film, which is placed on the screen. The screen is exposed to light, hardening the emulsion around the design. The unexposed emulsion (where the design is) is washed away, leaving a stencil of the design on the screen.

3. Setting Up the Printing Press:

The prepared screens are then mounted on a screen printing press. These presses can be manual or automatic, with automatic presses being more suitable for high-volume production. Each screen is aligned precisely to ensure that the design prints accurately.

4. Printing the Shirts:

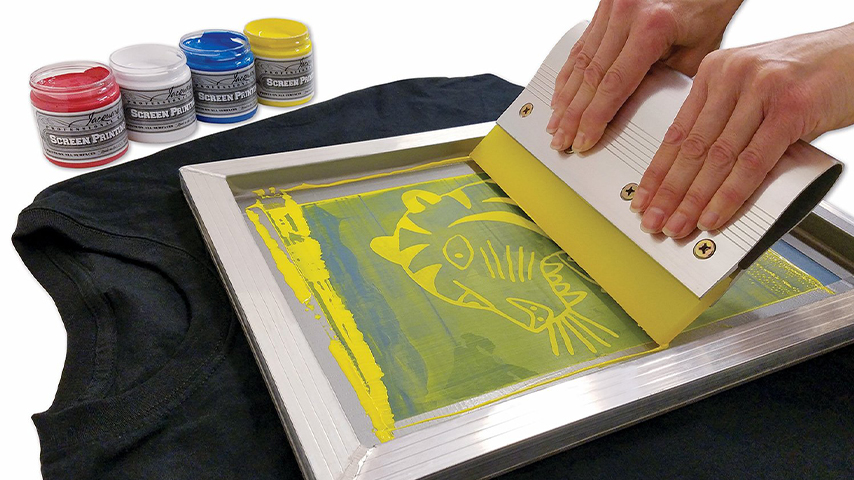

With the screens and press set up, the actual printing process begins. Shirts are placed on a platen (a flat board) to keep them in place. Ink is then applied to the screens, and a squeegee is used to push the ink through the mesh stencil onto the shirt. This process is repeated for each color in the design, with the shirt being dried between each color application to prevent smudging.

5. Curing the Ink:

Once the design is fully printed, the shirts must be cured to set the ink. This is usually done using a conveyor dryer, where the printed shirts pass through high temperatures that cure the ink, making it durable and resistant to washing and wear.

6. Quality Control and Finishing:

After curing, each shirt is inspected for quality to ensure that the print is sharp and the colors are accurate. Any necessary touch-ups are made, and the shirts are then ready to be packaged and delivered.

How Screen Printing Differs from Other Printing Methods

1. Durability:

Screen printing is renowned for its durability. The ink used in screen printing is thicker and more vibrant than inks used in other methods, making the prints last longer and withstand more washes. This makes screen printing ideal for producing high-quality, long-lasting custom shirts.

2. Color Vibrancy:

The use of thick, plastisol inks in screen printing results in vibrant and opaque colors, even on dark fabrics. This is a significant advantage over methods like Direct-to-Garment (DTG) printing, which may require a white underbase to achieve similar color vibrancy on dark materials.

3. Cost-Effectiveness for Large Orders:

Screen printing is highly cost-effective for large orders. Once the screens are prepared, the setup cost is spread across the number of shirts being printed, making it cheaper per unit for bulk orders. In contrast, methods like DTG printing, where each shirt is printed individually, can become expensive for large quantities.

4. Versatility with Fabrics:

Screen printing works well on a variety of fabrics, including cotton, polyester, and blends. This versatility makes it a preferred choice for custom apparel printing. Sublimation printing, on the other hand, is limited to polyester fabrics.

5. Detailed and Complex Designs:

While screen printing is excellent for bold and vibrant designs, it may not be the best choice for highly detailed or photographic images. Using a variety of colors and gradients, DTG printing is great for making complex and detailed patterns. Screen printing, however, is better suited for designs with fewer colors and simpler elements.

6. Setup and Preparation:

Screen printing involves more setup and preparation time compared to other methods like heat transfer or DTG printing. Each color in the design requires a separate screen, making the initial setup process more labor-intensive. However, once the setup is complete, the actual printing process is efficient and fast for large quantities.

Conclusion

Screen printing is a reliable and effective method for producing custom shirts, offering durability, vibrant colors, and cost-effectiveness for large orders. While it may involve more setup time and is best suited for simpler designs, its ability to create long-lasting prints on various fabrics makes it a favored choice for custom apparel. Understanding the differences between screen printing and other methods can help you choose the right technique for your custom shirt printing needs, ensuring you achieve the desired quality and effect for your designs.