Introduction

In the world of construction and design, materials that offer both functionality and aesthetic appeal are highly valued. One such material is Hollow Sheet Polycarbonate, also known as polycarbonate hollow sheets. These versatile sheets are becoming increasingly popular due to their remarkable properties and wide range of applications. This guide will delve into the features, benefits, uses, and frequently asked questions about PC hollow sheets, helping you understand why they might be the perfect choice for your next project.

What Are PC Hollow Sheets?

PC hollow sheets are made from polycarbonate, a type of durable and lightweight plastic. These sheets are characterized by their hollow, multi-layered structure, which consists of two flat sheets separated by vertical ribs. This design not only enhances their strength but also provides excellent thermal insulation and impact resistance.

Key Characteristics:

- Material: Polycarbonate, known for its high impact resistance and durability.

- Structure: Hollow core design with multiple layers and ribs for added strength.

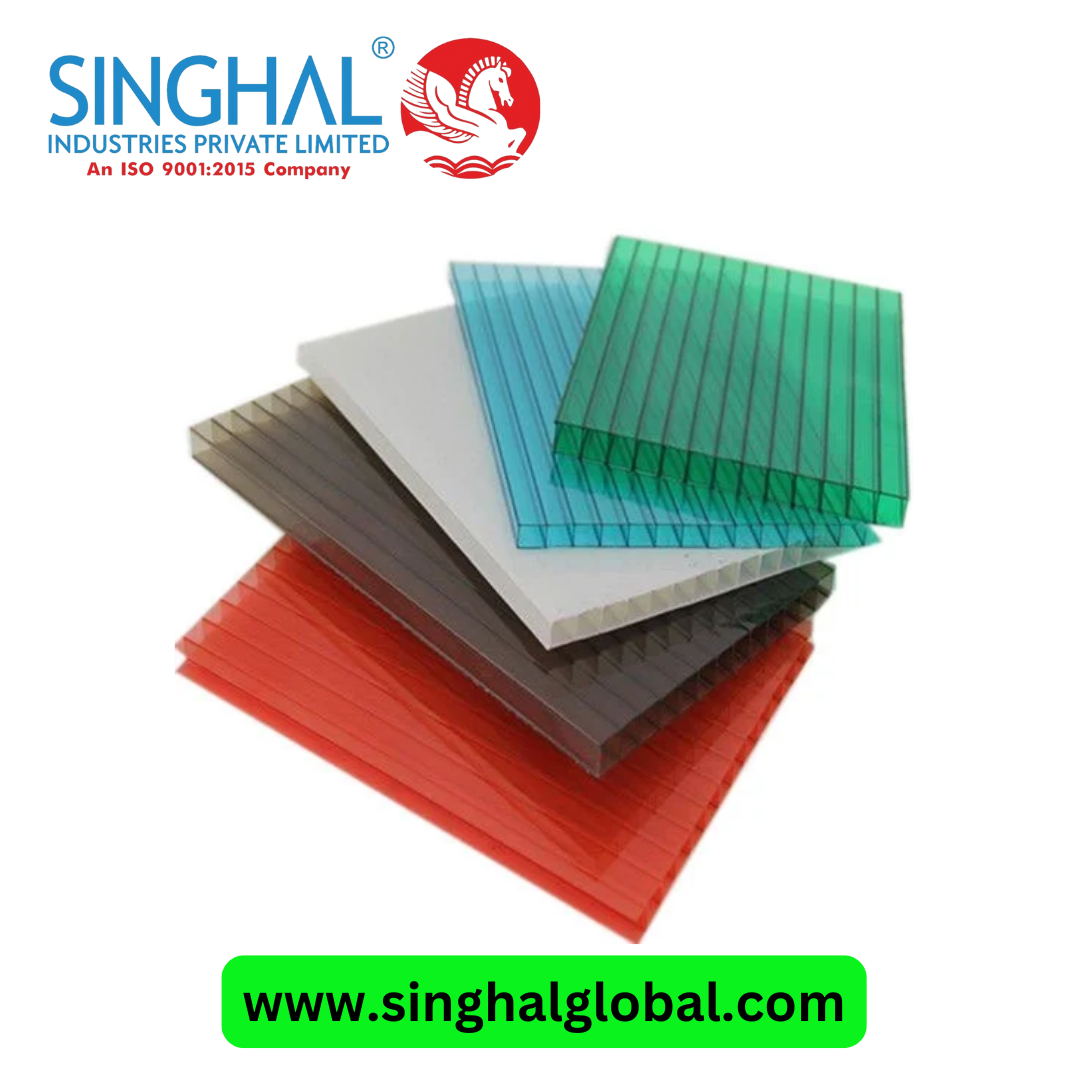

- Appearance: Available in various colors and finishes, including clear, frosted, and tinted options.

Benefits of PC Hollow Sheets

- Durability and Impact Resistance: PC hollow sheets are highly resistant to impact and can withstand harsh weather conditions. They are nearly unbreakable, making them an excellent choice for applications requiring high durability.

- Lightweight: Despite their strength, PC hollow sheets are relatively lightweight. This characteristic makes them easier to handle and install compared to heavier materials like glass or solid plastics.

- Thermal Insulation: The hollow core structure provides superior thermal insulation. This helps maintain stable indoor temperatures, reducing energy costs and improving comfort.

- UV Resistance: Many PC hollow sheets are treated with UV-resistant coatings, which protect them from yellowing and degradation caused by prolonged sun exposure. This makes them ideal for outdoor applications.

- Flexibility: PC hollow sheets can be easily cut, shaped, and formed, allowing for creative and custom designs. They can be used in various architectural and construction applications, from skylights to partitions.

- Transparency and Light Diffusion: These sheets can be manufactured in clear or translucent forms, allowing natural light to pass through while diffusing it to reduce glare. This property is particularly useful for greenhouses and lighting applications.

- Cost-Effective: PC hollow sheets offer a cost-effective alternative to traditional building materials. Their durability and low maintenance requirements contribute to their overall value.

Applications of PC Hollow Sheets

- Skylights and Roofing: Polycarbonate Hollow Sheet are widely used in skylights and roofing systems due to their transparency and thermal insulation properties. They allow natural light to illuminate indoor spaces while providing protection from the elements.

- Greenhouses: The excellent light diffusion and thermal insulation properties of PC hollow sheets make them ideal for greenhouse applications. They help create a controlled environment for plant growth while reducing heating costs.

- Partition Walls: In both commercial and residential settings, PC hollow sheets are used for partition walls and room dividers. Their lightweight nature and customizable appearance make them a popular choice for modern interiors.

- Pergolas and Canopies: PC hollow sheets are often used in outdoor structures like pergolas and canopies. They provide protection from rain and UV rays while maintaining a light, airy feel.

- Signage and Displays: Due to their versatility and ease of fabrication, PC hollow sheets are used in signage and display applications. They can be easily cut and shaped to create eye-catching displays.

- Architectural Features: Designers and architects use PC hollow sheets to create unique architectural features and facades. Their flexibility and range of finishes allow for innovative design solutions.

Conclusion

PC hollow sheets offer a versatile and durable solution for a wide range of construction and design needs. Their combination of strength, lightness, and thermal insulation makes them an attractive option for everything from skylights to greenhouses. By understanding their benefits, applications, and maintenance requirements, you can make informed decisions about incorporating PC hollow sheets into your next project. Whether you’re a builder, designer, or homeowner, Hollow Polycarbonate Sheet provide a reliable and cost-effective material choice for enhancing both functionality and aesthetics.

FAQs About PC Hollow Sheets

1. How do PC hollow sheets compare to glass?

PC hollow sheets are much lighter than glass and offer superior impact resistance. While glass is prone to breaking under stress, PC hollow sheets are highly durable and less likely to shatter. They also provide better thermal insulation and UV resistance.

2. Can PC hollow sheets be used in extreme weather conditions?

Yes, PC hollow sheets are designed to withstand a wide range of weather conditions, including heavy rain, snow, and strong winds. Their impact resistance and UV protection make them suitable for both hot and cold climates.

3. How do you install PC hollow sheets?

Installation methods vary depending on the application, but generally, PC hollow sheets can be installed using standard construction techniques. They can be cut to size with a circular saw and secured with screws or brackets. It’s important to follow manufacturer guidelines to ensure proper installation and sealing.

4. Are PC hollow sheets easy to maintain?

Yes, PC hollow sheets require minimal maintenance. They can be cleaned with mild soap and water. Avoid using abrasive cleaners or solvents, as these can damage the surface. Regular cleaning will help maintain their clarity and appearance.