Polypropylene (PP) corrugated sheets, commonly referred to as corrugated plastic sheets, have emerged as an essential material in various industries. Known for their lightweight, durable, and versatile characteristics, these sheets offer solutions in a wide array of applications, including packaging, advertising, construction, and agriculture. The unique structure of corrugated plastic sheets provides superior protection and flexibility compared to traditional materials like wood or cardboard, making them an excellent alternative. This Pulkit Plastic Products will explore the composition, benefits, applications, and rising demand for PP corrugated sheets, with a focus on the role of corrugated plastic sheet manufacturers in meeting this global demand.

What are PP Corrugated Sheets?

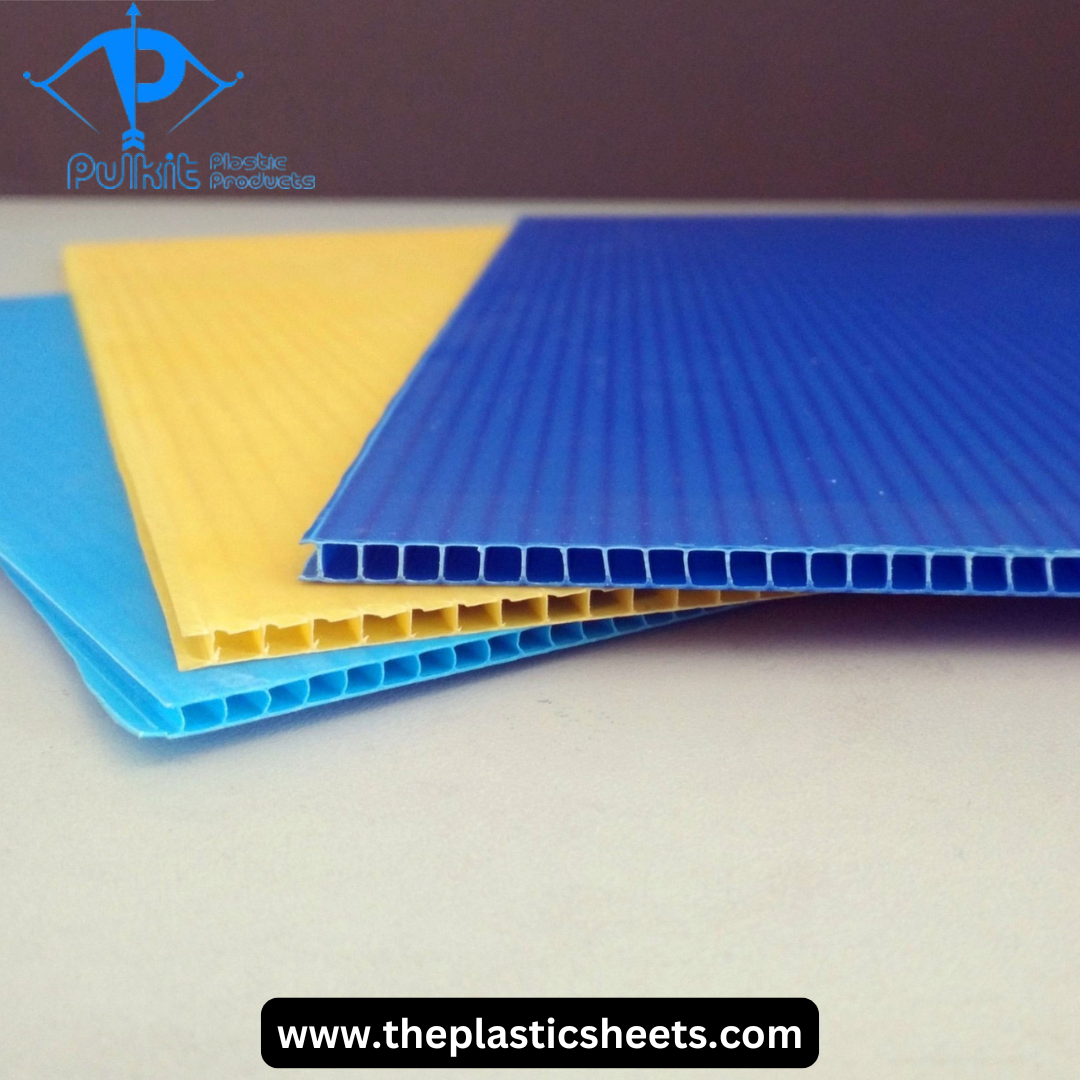

PP corrugated sheets are made from polypropylene, a thermoplastic polymer known for its high durability and resistance to chemicals, moisture, and impact. These sheets consist of two flat layers of polypropylene that sandwich a fluted layer, creating a hollow yet structurally strong material. This construction makes PP corrugated sheets lightweight but still capable of withstanding substantial wear and tear. Due to their robustness and ability to resist environmental factors, corrugated plastic sheets are widely used in various industries, particularly where durability and cost-efficiency are essential.

Corrugated plastic sheet manufacturers produce these sheets in various sizes, thicknesses, and colors, catering to the specific needs of different industries. Their adaptability makes them ideal for applications ranging from packaging delicate items to creating protective barriers in construction projects. The material’s versatility is also evident in its ability to be cut, shaped, and molded into different forms, which has expanded its use in creative sectors like advertising and display manufacturing.

Applications of PP Corrugated Sheets in Different Industries

One of the most prominent uses of PP corrugated sheets is in the packaging industry. Corrugated plastic sheets are widely used for creating packaging boxes and containers that need to be both lightweight and durable. Unlike cardboard, PP corrugated sheets can withstand water, chemicals, and extreme temperatures, making them ideal for shipping and storing items in challenging environments. In agriculture, these sheets are used to build temporary enclosures, protective covers, and storage units due to their resistance to UV rays and moisture.

Another significant application is in the advertising and signage industry. Corrugated plastic sheets serve as the material of choice for outdoor signs, display boards, and promotional stands. Their lightweight nature makes them easy to transport and install, while their ability to resist fading from sunlight ensures that the signage remains clear and readable for extended periods. Corrugated plastic sheet manufacturers often provide customization options, allowing businesses to print logos, designs, and messages directly onto the sheets.

In construction, PP corrugated sheets are used as temporary protective barriers for surfaces and floors, preventing damage during renovations or new builds. These sheets can also serve as lightweight wall partitions or roofing material in temporary structures. Additionally, their chemical resistance and durability make them suitable for use in environments where exposure to harsh elements is frequent.

Advantages of Corrugated Plastic Sheets

The advantages of Corrugated Plastic Sheet Manufacturers are numerous, making them a popular choice across many sectors. One of the primary benefits is their lightweight composition, which makes them easy to handle and install without compromising on strength. This feature is particularly valuable in industries like packaging and construction, where ease of use and efficiency are crucial. Additionally, PP corrugated sheets are incredibly durable and resistant to environmental factors such as moisture, UV rays, and chemicals, which allows them to maintain their integrity even in harsh conditions.

Corrugated plastic sheets are also highly cost-effective. Compared to traditional materials like wood or metal, they are significantly cheaper while offering similar, if not superior, performance. Their recyclability further adds to their cost-efficiency, as companies can reuse or repurpose the material, reducing overall waste and material costs. Corrugated plastic sheet manufacturers have capitalized on these advantages by offering sheets that meet the specific needs of different industries while ensuring affordability.

Another notable advantage is the customizability of PP corrugated sheets. These sheets can be produced in a wide range of sizes, colors, and thicknesses, making them suitable for various applications. For example, in the advertising industry, the ability to print directly onto the sheet surface makes it an attractive option for branding and promotional activities. The versatility of the material has positioned corrugated plastic sheets as a go-to solution for companies looking for flexible yet durable materials.

Environmental Impact and Sustainability of PP Corrugated Sheets

As industries worldwide become more environmentally conscious, the sustainability of materials has become a key consideration. One of the significant benefits of PP corrugated sheets is that they are 100% recyclable. Polypropylene, the primary component of these sheets, can be melted down and reformed into new products without degrading in quality. This recyclability reduces waste and the need for new raw materials, making corrugated plastic sheets a more sustainable option compared to non-recyclable materials like metal or wood.

Moreover, the durability of PP corrugated sheets ensures a longer lifespan, which translates to fewer replacements and less waste. Unlike cardboard or other degradable materials, which may need frequent replacement due to wear and tear, PP corrugated sheets can be reused multiple times before needing to be recycled. This reduces the overall environmental impact of the material, making it an ideal choice for businesses aiming to lower their carbon footprint.

Corrugated plastic sheet manufacturers are increasingly focusing on producing eco-friendly products by optimizing their production processes and encouraging recycling practices. As the demand for sustainable materials grows, the role of recyclable and durable materials like PP corrugated sheets will likely continue to expand across industries.

Corrugated Plastic Sheet Manufacturers: Meeting Global Demand

The growing demand for Corrugated Plastic Sheet has led to a rise in corrugated plastic sheet manufacturers across the globe. These manufacturers have become key players in supplying industries with versatile, high-quality, and cost-effective materials. Many manufacturers have adopted advanced production techniques to create sheets that meet the specific requirements of different sectors, whether it’s packaging, construction, or advertising. This adaptability has allowed them to cater to both domestic and international markets.

India, in particular, has emerged as a significant hub for the production of PP corrugated sheets, with numerous corrugated plastic sheet manufacturers offering competitive pricing and high-quality products. The country’s expanding manufacturing capabilities, combined with its access to raw materials, has made India a leading exporter of corrugated plastic sheets worldwide. As industries continue to shift towards more sustainable and durable materials, the demand for high-performance products like PP corrugated sheets is expected to grow, positioning these manufacturers for continued success.

Customization and Innovation in PP Corrugated Sheets

One of the driving factors behind the popularity of PP corrugated sheets is the level of customization and innovation offered by manufacturers. Modern corrugated plastic sheet manufacturers are equipped with state-of-the-art technology that allows them to produce sheets in a variety of sizes, shapes, and colors to meet the specific needs of their clients. Customization options also include surface treatments such as anti-static coatings, flame retardants, and UV stabilizers, which enhance the performance of the sheets in different environments.

Innovation has also played a significant role in the development of PP corrugated sheets. Many manufacturers have invested in research and development to create new formulations that enhance the strength, durability, and environmental impact of their products. These innovations have led to the creation of lightweight yet incredibly durable sheets that can withstand extreme conditions without compromising performance. As industries continue to evolve, the need for innovative materials like PP corrugated sheets will become increasingly important.

Key Considerations When Choosing PP Corrugated Sheets

When selecting PP corrugated sheets for industrial or commercial use, there are several key factors to consider to ensure that the material meets your needs. The first consideration is the sheet’s thickness, which will impact its durability and strength. Thicker sheets offer greater protection and durability, making them ideal for heavy-duty applications, while thinner sheets may be more suitable for lightweight packaging or temporary signage.

Another important factor is the sheet’s resistance to environmental factors. For outdoor applications, UV resistance is crucial to prevent the sheet from degrading under prolonged sunlight exposure. Similarly, for applications that involve exposure to moisture or chemicals, it is essential to select sheets that have been treated to withstand these elements. Corrugated plastic sheet manufacturers often offer specialized coatings that enhance the material’s performance in specific environments, ensuring that you can find a product tailored to your needs.

Conclusion

PP corrugated sheets have become an indispensable material across various industries due to their durability, lightweight nature, and cost-effectiveness. As the demand for eco-friendly and versatile materials grows, corrugated plastic sheets have proven to be a sustainable solution for packaging, construction, advertising, and many other applications. With Corrugated Plastic Sheets continuously innovating and improving the performance of these materials, PP corrugated sheets are set to play an even larger role in industrial and commercial sectors worldwide.

Frequently Asked Questions (FAQs)

What are PP corrugated sheets made of?

PP corrugated sheets are made from polypropylene, a durable thermoplastic polymer that is lightweight, strong, and resistant to environmental factors like moisture, UV rays, and chemicals.

What industries commonly use PP corrugated sheets?

PP corrugated sheets are widely used in industries such as packaging, construction, agriculture, and advertising for creating packaging boxes, protective barriers, signage, and temporary enclosures.

How do PP corrugated sheets contribute to sustainability?

PP corrugated sheets are 100% recyclable, which reduces waste and the need for new raw materials. Their long lifespan and durability also make them a more sustainable option compared to traditional materials like cardboard or wood.

What should I consider when choosing PP corrugated sheets for my application?

When selecting PP corrugated sheets, consider factors such as thickness, environmental resistance (UV, moisture, chemicals), and whether additional coatings or treatments are necessary for your specific use case.