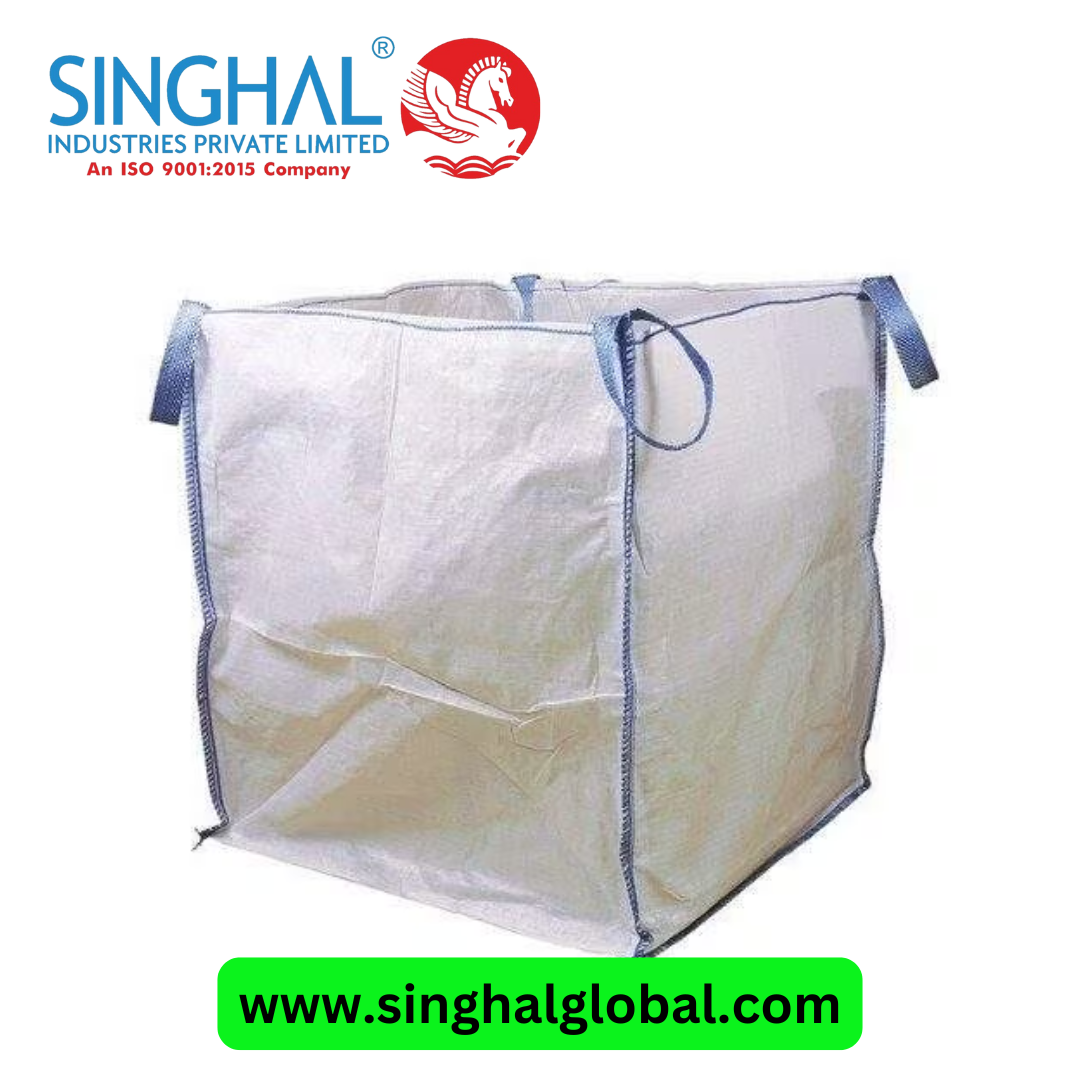

In the realm of bulk packaging, Jumbo Bag Plastic have become a go-to choice for industries requiring durable and cost-effective solutions. These versatile bags, also known as polypropylene jumbo bags or FIBCs (Flexible Intermediate Bulk Containers), are essential for transporting and storing a wide variety of materials. This comprehensive guide will delve into the characteristics, benefits, and common applications of PP jumbo bags, providing answers to frequently asked questions to help you make informed decisions.

What Are PP Jumbo Bags?

PP jumbo bags are large, sturdy bags made from polypropylene (PP), a type of plastic known for its strength and flexibility. Designed to handle bulk quantities, these bags are used across multiple industries for packaging and transporting goods. Their flexible nature allows them to be folded and stored efficiently when not in use, making them a practical solution for various bulk handling needs.

Types of PP Jumbo Bags

1. Standard Jumbo Bags

Standard PP jumbo bags are the most commonly used type. They feature a simple design with a top opening and a bottom outlet, often secured with drawstrings or flaps. These bags are ideal for general bulk packaging needs, including grains, chemicals, and construction materials.

2. Baffle Bags

Baffle bags are equipped with internal baffles or partitions that help the bag maintain its shape and stability. This design prevents bulging and allows for efficient stacking and storage. Baffle bags are suitable for products that require more precise handling, such as food ingredients or pharmaceuticals.

3. Ventilated Bags

Ventilated PP jumbo bags include built-in ventilation or mesh panels that allow air to circulate through the bag. This design is particularly beneficial for products that are sensitive to moisture or need to breathe, such as agricultural products or certain chemicals.

4. Conductive Bags

Conductive PP jumbo bags are made with materials that dissipate static electricity, preventing static discharge that could potentially damage electronic components or sensitive materials. These bags are essential in the electronics industry and other sectors where static control is critical.

5. Custom Bags

Many suppliers offer customizable PP jumbo bags to meet specific needs. Custom features may include different sizes, shapes, colors, printing options, and additional functionalities like built-in handles or liners. Customization helps businesses tailor the packaging to their exact requirements.

Benefits of PP Jumbo Bags

1. Durability and Strength

One of the most significant advantages of Jumbo Bag Price is their durability. Made from high-quality polypropylene, these bags can withstand heavy loads and harsh conditions. They resist tearing, puncturing, and abrasions, making them suitable for transporting a wide range of materials.

2. Cost-Effectiveness

PP jumbo bags are an economical choice for bulk packaging. Their lightweight design reduces shipping costs, and their manufacturing process is more affordable compared to rigid packaging alternatives like drums or crates. The cost-effectiveness of these bags makes them a popular choice for many industries.

3. Versatility

PP jumbo bags are incredibly versatile and can be used for various applications. Whether you’re packaging agricultural products, construction materials, or chemicals, there’s likely a PP jumbo bag that suits your needs. The flexibility in design allows businesses to choose the most appropriate bag for their specific products.

4. Space Efficiency

Due to their flexible nature, PP jumbo bags can be folded or collapsed when not in use, optimizing storage space. Their ability to conform to the shape of their contents also helps maximize storage efficiency, reducing the overall footprint required for packaging and transportation.

5. Recyclability

Polypropylene is a recyclable material, and many PP jumbo bags can be recycled at the end of their lifecycle. This aspect contributes to reducing the environmental impact of packaging waste, aligning with sustainability goals and eco-friendly practices.

Common Applications of PP Jumbo Bags

1. Agriculture

In the agricultural sector, PP jumbo bags are used for packaging and transporting grains, seeds, fertilizers, and other bulk agricultural products. Their durability and ventilation options (for some models) make them ideal for protecting products from moisture and pests.

2. Construction

PP jumbo bags are widely used in the construction industry for handling and transporting materials such as sand, gravel, cement, and aggregates. Their strength and load-bearing capacity make them suitable for carrying heavy construction materials.

3. Chemicals

For the chemical industry, PP jumbo bags offer a reliable solution for packaging and transporting various chemicals and powders. Conductive bags are particularly important in this sector to prevent static discharge that could lead to accidents or contamination.

4. Food Industry

In the food industry, PP jumbo bags are used for packaging bulk food ingredients like flour, sugar, and grains. The bags can be designed with food-grade materials and features to ensure the safety and freshness of the contents.

5. Recycling and Waste Management

PP jumbo bags are also utilized in recycling and waste management operations. They are used for collecting and transporting recyclable materials or waste, helping to streamline the recycling process and manage waste effectively.

How to Choose the Right PP Jumbo Bag

1. Determine the Material Requirements

Different types of PP jumbo bags offer varying levels of strength, durability, and resistance to environmental factors. Choose a bag that matches the specific requirements of your product, whether it’s a standard bag for general use or a specialized bag for sensitive materials.

2. Assess Size and Capacity

PP jumbo bags come in various sizes and capacities. Ensure the bag you select can accommodate the volume of material you need to package. Choosing the right size helps prevent overloading and ensures efficient handling.

3. Consider Additional Features

Depending on your needs, you might require additional features such as ventilation, baffles, or conductive properties. Evaluate these features when selecting a PP jumbo bag to ensure it meets your specific application requirements.

4. Verify Quality and Compliance

Ensure that the PP jumbo bags you choose are manufactured to high-quality standards and comply with relevant industry regulations. This is especially important for applications in the food or pharmaceutical industries, where quality and safety are paramount.

5. Explore Customization Options

If you have specific branding or functional requirements, consider exploring customization options. Customization can include printing, sizes, colors, and additional features that enhance the functionality and appearance of the bags.

Conclusion

The Jumbo Plastic Bag are a versatile and practical packaging solution that offers numerous benefits for bulk handling across various industries. Their durability, cost-effectiveness, and customizable features make them an excellent choice for transporting and storing a wide range of materials. By understanding the different types of PP jumbo bags, their benefits, and how to select the right one for your needs, you can enhance your packaging strategy and ensure efficient, reliable bulk handling. Whether you’re involved in agriculture, construction, or any other sector requiring bulk packaging, PP jumbo bags provide a robust and adaptable solution to meet your needs.

Frequently Asked Questions

1. What is the maximum load capacity of PP jumbo bags?

PP jumbo bags typically have a load capacity ranging from 500 to 2,000 kilograms (1,100 to 4,400 pounds), depending on the design and material strength. It’s important to choose a bag with a capacity suitable for your specific needs to avoid overloading.

2. Are PP jumbo bags reusable?

Yes, PP jumbo bags can be reused multiple times if they are properly maintained and handled. However, the possibility of reuse depends on the type of material and the condition of the bag after use. Always inspect the bags for damage before reuse.

3. How should PP jumbo bags be stored?

PP jumbo bags should be stored in a cool, dry place away from direct sunlight and extreme temperatures. Proper storage helps maintain the quality and integrity of the bags and ensures they remain in good condition for future use.