Choosing the right electronics manufacturing services or EMS provider can be pivotal for your business. The complexity and scale of modern electronics can be daunting, especially when you consider the intricacies involved in production, assembly, and testing. This write-up is here to demystify the process, ensuring you make well-informed decisions that propel your projects to success.

What Are Electronic Manufacturing Services?

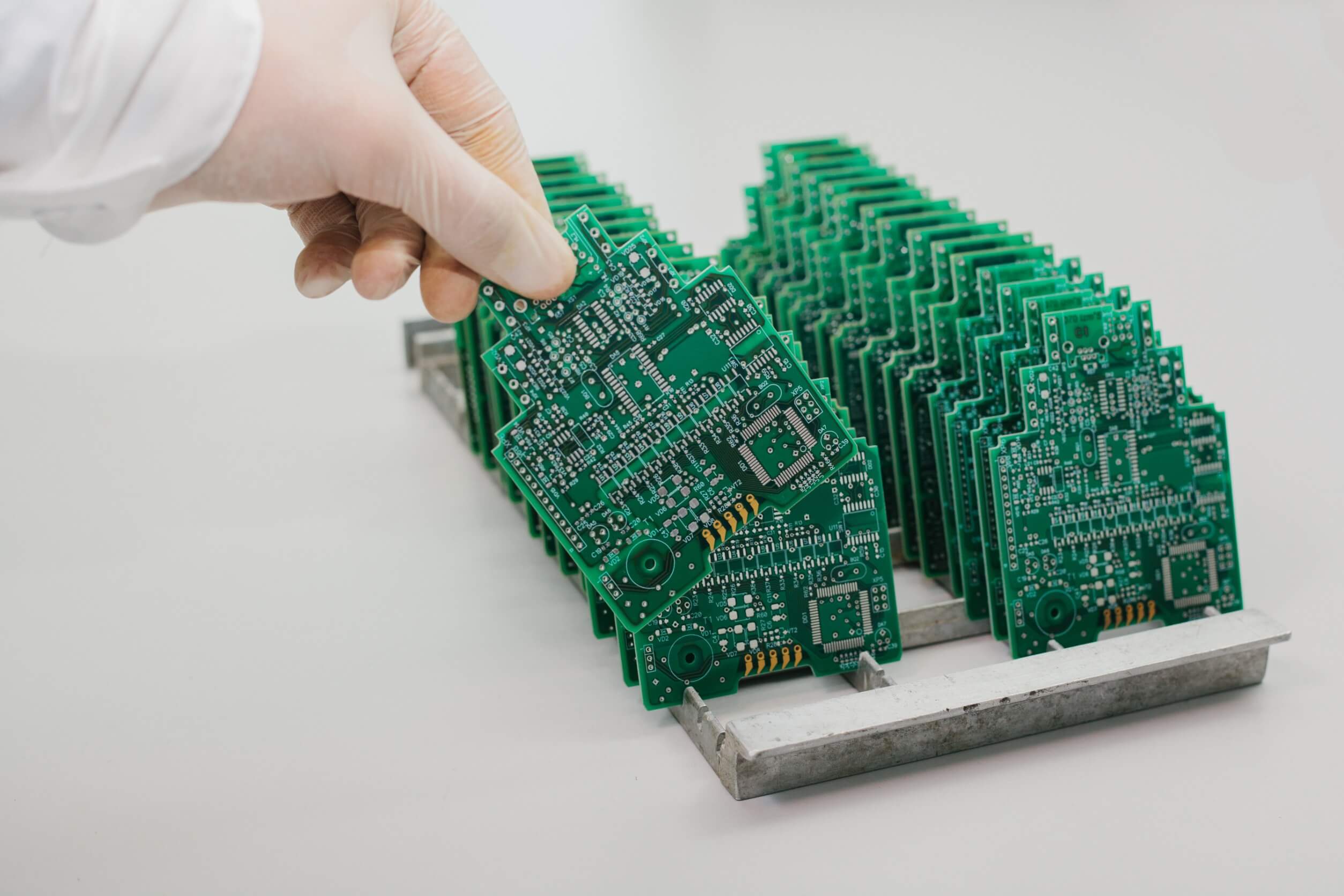

It refers to companies that design, manufacture, test, distribute, and provide return/repair services for electronic components and assemblies. These services can range from producing simple circuit boards to complex, multifaceted electronics that integrate software and hardware.

The Importance of EMS Providers

EMS providers play a crucial role in the tech industry. They help businesses scale their production, improve product quality, and reduce costs. By outsourcing the manufacturing process, companies can focus on their core competencies, such as R&D and sales, while leaving the intricacies of production to the experts.

8 Factors to Choose an EMS Provider

- Technical Expertise and Capabilities

When evaluating potential EMS providers, one of the first aspects to consider is their technical expertise and capabilities. Does the provider have experience with the type of products you are manufacturing? What technologies and processes do they specialize in?

For instance, if your product involves advanced microelectronics, you will want a provider skilled in that area. Review their portfolio and case studies to ensure they have the necessary experience.

- Quality Assurance and Certifications

Quality assurance is paramount in electronics manufacturing. Look for EMS providers that adhere to stringent quality standards and hold relevant certifications, such as ISO 9001.

Certifications indicate that a provider follows industry best practices and has robust quality management systems in place. This reduces the risk of defects and ensures high-quality products.

- Supply Chain Management

A well-managed supply chain is essential for timely and cost-effective production. Evaluate the EMS provider’s supply chain management capabilities. Do they have strong relationships with reliable suppliers? How do they handle component sourcing and inventory management?

Effective supply chain management helps mitigate risks related to component shortages and delays, ensuring smooth and consistent production.

- Flexibility and Scalability

Your business needs can change over time, making flexibility and scalability key factors in choosing an EMS provider. Can the provider scale production up or down based on your requirements? Are they capable of adapting to changes in design or production volume?

A flexible EMS provider can accommodate your growth and evolving needs, preventing production bottlenecks and facilitating innovation.

- Cost Efficiency and Pricing

Cost is always a critical consideration. Compare pricing models among electronic manufacturing services providers to ensure you’re getting value for your money. Remember, the cheapest option isn’t always the best. Factor in the total cost of ownership, including hidden costs like rework, delays, and quality issues.

Request detailed quotes and evaluate how pricing aligns with your budget and long-term financial goals. Transparency in pricing is a good indicator of a reliable partner.

- Communication and Customer Support

Effective communication is vital for successful collaboration. Assess the EMS provider’s communication channels and customer support. How responsive are they to inquiries? Do they provide clear and regular updates on project status?

Strong communication ensures that you stay informed and can address any issues promptly, leading to smoother project execution.

- Geographic Location

The location of your EMS provider can impact production timelines, shipping costs, and overall efficiency. Consider whether a local or offshore provider better suits your needs. Local providers may offer faster turnaround times and easier collaboration, while offshore providers might provide cost advantages.

Weigh the pros and cons of each option based on your specific requirements and logistical considerations.

- Reputation and References

At last, research the reputation of potential EMS providers. Look for reviews, testimonials, and case studies from previous clients. Ask for references and follow up with them to gauge their satisfaction with the provider’s services.

A provider with a solid reputation and positive client feedback is more likely to deliver reliable and high-quality services.

Final Thoughts

Choosing the right electronic manufacturing services or EMS provider is essential for the success of your electronic products. By considering factors like technical expertise, quality assurance, supply chain management, and cost efficiency, you can make an informed decision that aligns with your business goals.

Remember, the right EMS partner is not just a service provider but an extension of your team. They can help you scale, innovate, and deliver superior products to market. Take your time to evaluate your options and choose a partner who shares your vision and commitment to excellence.